Tube making is a significant function of industries such as automobile, construction, aviation, and furniture industries. In Canada, the producers are concentrating on sustainability and thinking of techniques to minimize waste and conserve energy while still making accurate and long-lasting components. Among the methods that have improved in this context is mandrel bending. Precisely known, mandrel bending is also fast becoming famous for its environmental aspects.

What Sets Mandrel Bending Apart

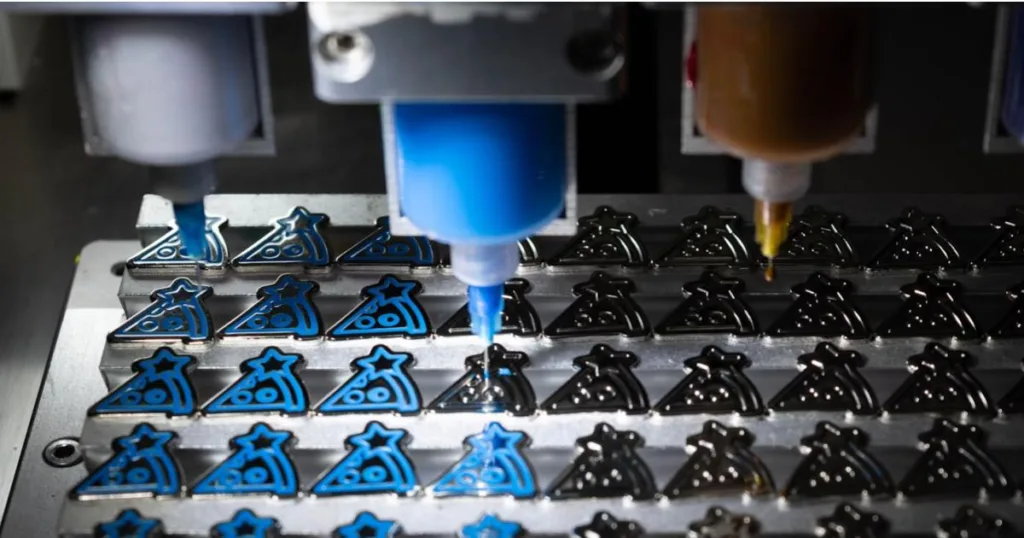

Mandrel bending refers to the application of a mandrel, a firm rod or elastic tool, inserted within a tube when bending. This ensures against wrinkling, flattening, and deformation that may happen with other bending processes. It produces a smooth, consistent bend with minimal material loss.

To makers, this means greater efficiency. To the environment, it means reduced scrap metal and reduced waste material. Each tube bent right the first time saves resources and energy expended on rework.

Why Sustainability in Tube Fabrication Matters

Canadian businesses are being pressed to balance efficiency with environmental stewardship. Customers and regulators alike are demanding more environmentally friendly practices. For tube fabricating, this means minimizing waste, reducing material usage, and decreasing the consumption of energy.

Mandrel bending is aligned with these objectives by nature. In reducing mistakes and optimizing precision, it limits the quantity of raw material converted into scrap. This is environmentally friendly as well as for manufacturers who are not charged with the expense of having to buy more metal to replace unnecessary stock.

Sustainable Benefits of Mandrel Bending

Mandrel bending enables sustainability on a number of levels:

- Less Waste

Historical bending processes tend to warp or collapse tubes, usually necessitating recycling of the component. Mandrel bending with precision eliminates such mistakes, reducing waste.

- Material Efficiency

Less trimming is required since bends are tighter and smoother. More functional parts per unit of tubing are produced by the manufacturer.

- Less Energy Consumption

Fewer mistakes mean less re-work. Each re-bend saved is power that would have been wasted in running the machines again.

- Increased Lifespan of Products

Higher-quality bends make stronger tubes that will last longer in their end-use applications. Products with a longer lifespan have to be replaced less, and this maintains.

Trends in Canadian Tube Fabrication

Canadian fabrication sustainability is more than just efficiency. It is also a wider trend that finds businesses changing their production methods. Among the wider trends are:

- Green Materials: More and more businesses are using low-impact or recycled metals. Mandrel bending is especially ideal for this type of material since it prevents the chance of ruining the material while being shaped.

- Energy-Smart Workshops: The workshops are purchasing energy-efficient machines and streamlining processes to reduce power usage.

- Digital Integration: CAD technology and computer modeling enable the manufacturers to design bends in a virtual environment before the first cut reduces trial and error even further.

- Client Demand: End-users themselves demand environment-friendly practices, which compels fabrication firms to adopt cleaner means such as mandrel bending.

Applications in the Real World

Green mandrel bending is making its entry into various Canadian industries:

- Automotive: Cars need precise tubing for fuel systems and exhausts. Mandrel bending is robust and saves material waste, aligning with the trend of the auto industry’s adoption of greener practices.

- Construction: Structural and decorative purposes are frequently used by bent tubing in building designs. Green bending processes cut carbon emissions in construction.

- Furniture and Appliances: Mandrel bending produces smooth, long-lasting designs and reduces waste in production.

- Aerospace: Strength tubing that is light is the focus of aerospace. High-precision bending equates to fewer rejected parts, meaning less time and money spent.

Challenges to Overcome

As mandrel bending is efficient and environmentally friendly, there are still challenges for Canadian companies. The equipment itself is expensive, so smaller workshops are deterred from spending. Trained personnel also have to operate the process, and training takes a long time.

In spite of this, the long-term cost savings in material and energy usually prevail above these obstacles. As more and more organizations take up the technology, the advantages become clearer and clearer, prompting others to take it up.

The Future of Green Tube Fabrication

In the future years, mandrel bending will be at the forefront of Canada’s greening of manufacturing. As sustainability is no longer trendy, but routine, the companies that adopt lean techniques early in the game will be the leaders. We can expect:

- Increased application of computer software to precisely calculate bends prior to manufacturing.

- Increased application of recycled metals along with eco-bending practices.

- Expanding in applications such as electric vehicles that require a tremendous amount of accurate tubing but also require environmentally friendly methods of production.

The union of precision, long-term usage, and waste reduction makes mandrel bending the perfect choice for the future where sustainability is performance.

Conclusion

Eco-friendly mandrel bending is more than just methodology. It is an entire transformation of Canada’s tube manufacturing sector to more environmentally friendly processes. With energy conservation, reduction of wastes, and greater efficiency, mandrel bending realizes environmental as well as business objectives.

As Canadian businesses keep pushing the boundaries of innovation, mandrel tube bending will be an integral component of creating a cleaner, more efficient future.